Why Sei Laser

Provide you with the most professional Laser system solutions

R&D and production: strong R&D capabilities, advanced production control

The software and firmware that control SEI Laser systems are developed by our Software R&D Department that satisfies the different customers’ requests in real time.

The high quality and high stability products are derived from the continuous pursuit of the details of Shiyi Laser. thanks to 5 departments (mechanical, electronic and optoelectronic, software, mechanical design and production) which follow all the stages of the production process.

01

02

4.0 INDUSTRY: EASY INTEGRATION IN THE DIGITAL WORKFLOW

All SEI Laser systems moreover are certifed to satisfy the following requirements: control by CNC (Computer Numerical Control) and / or PLC (Programmable Logic Controller); interconnection with the company IT system thanks to remote loading of instructions and / or part program; automated integration with the logistic system of the company or with the supply chain; easy and intuitive interface between the operator and the machine;

compliance with the most recent parameters of safety and health at work

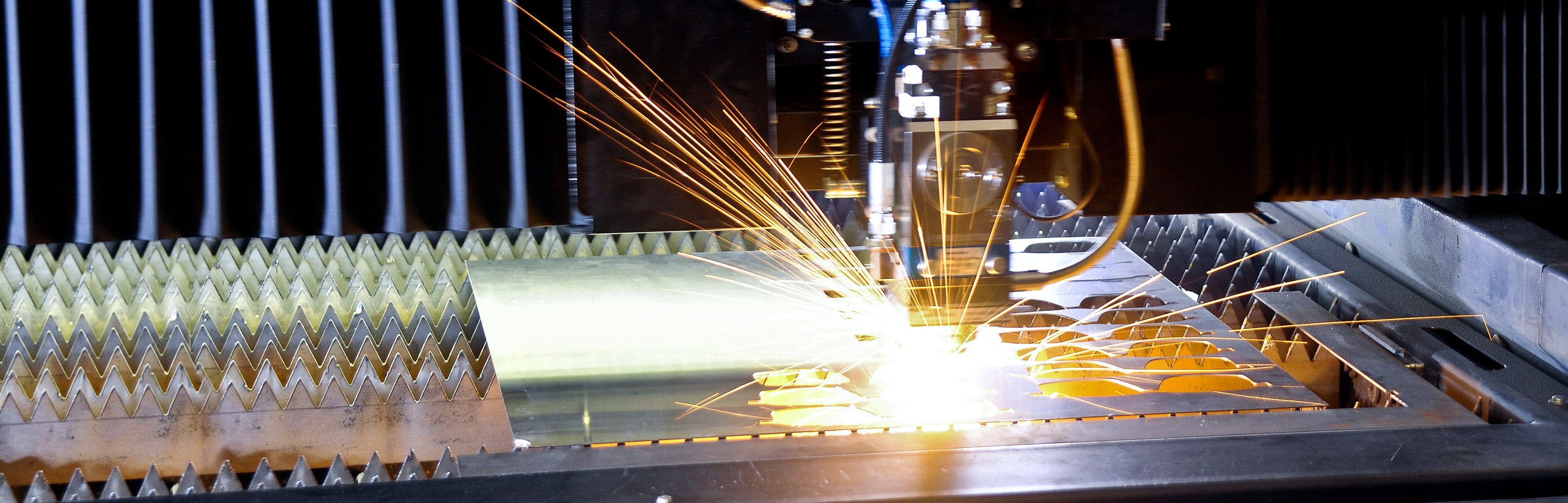

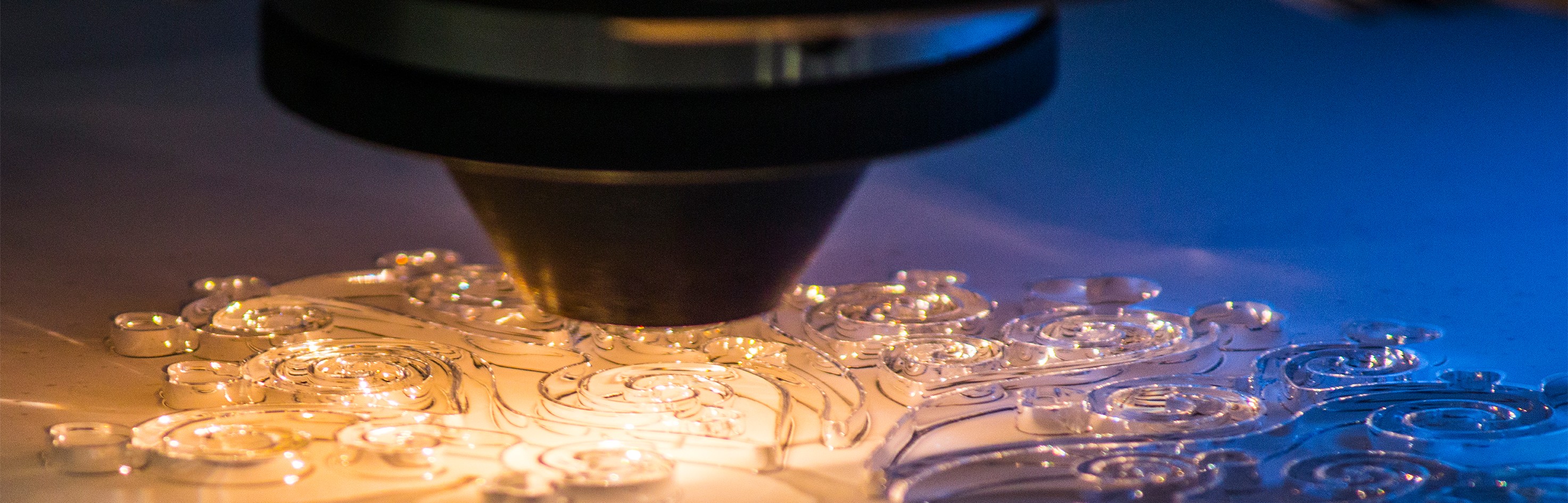

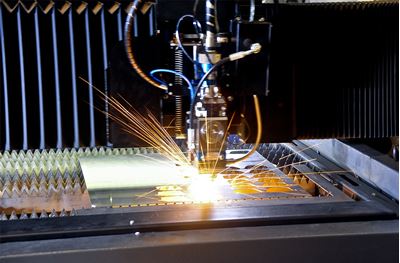

Product diversification: cost-effective laser equipment for all industries

Thanks to the complete range of laser systems developed by our R&D department, SEI Laser is able to satisfy the application needs of customers in both vertical and horizontal markets,including: Textile, Interior Design, Automotive, Lighting, Visual Communication, Graphic Arts, Converting, Labelling, Flexible Packaging, Folding

Carton, Furnishing and Metal processing.

Thanks to our know-how and continued investments, we provide laser systems that guarantee signifcant performances in terms of cost, operational efciency and final quality product.

03

Fast service: service system to solve all concerns

SEI Laser, thanks to its wide range of technical support services and its strong presence worldwide,ensures a quick, effective and tailored response to the different customer needs.

In addition to technical support on-site, SEI Laser offers a valued remote assistance.

The communication between the company and the customer, managed in real-time via chat,allows the operator to be guided step by step in the following technical operations:

• visualization and modifcation of the machine confguration parameters

• visualization and modifcation of the processing parameters

• diagnostics of the laser source and the control parts

• file transfer

• software upgrade

• productivity report

04

-

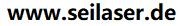

FLEXI DENIMThe innovative digital laser machine for jeans and fabric garments finishing.

FLEXI DENIMThe innovative digital laser machine for jeans and fabric garments finishing. -

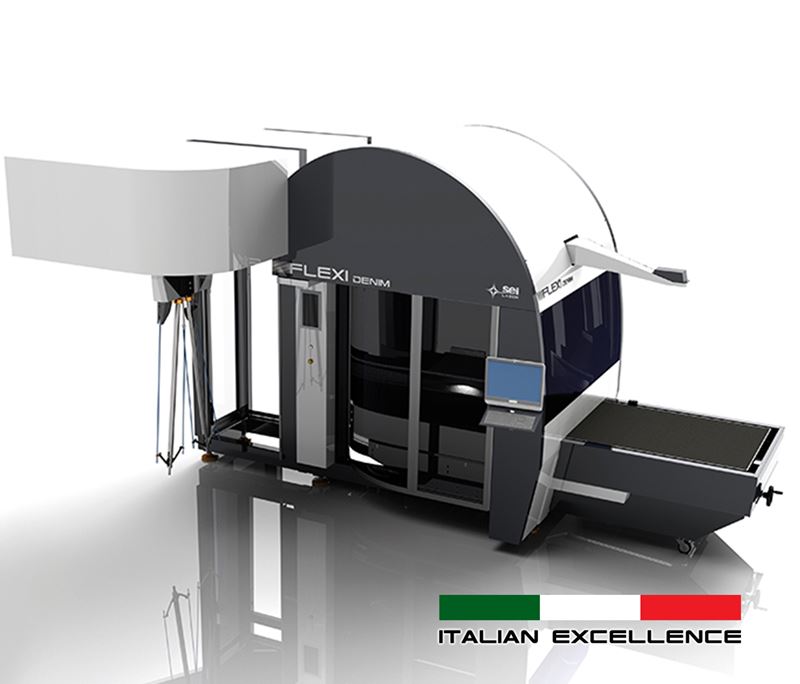

MATRIX TEXTILEThe “high-end” laser machine for textile roll processing with laser technology

MATRIX TEXTILEThe “high-end” laser machine for textile roll processing with laser technology -

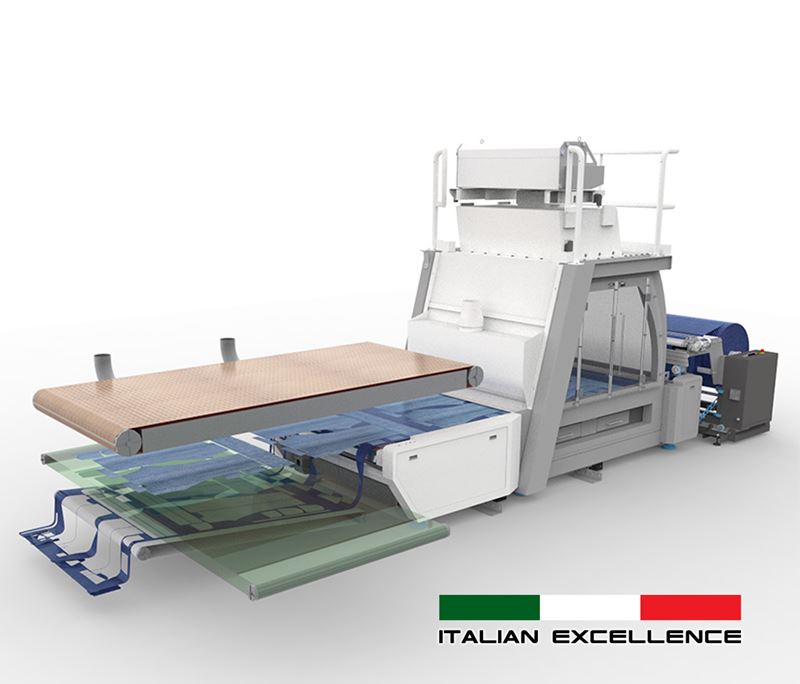

X-TYPE LINEUnmatchable laser cutting speed and accuracy

X-TYPE LINEUnmatchable laser cutting speed and accuracy -

NRGL TEXTILEThe new laser system for textile roll cutting and marking: high speed, high quality, high productivity

NRGL TEXTILEThe new laser system for textile roll cutting and marking: high speed, high quality, high productivity -

LABELMASTERThe most complete and professional laser machine “roll to roll” for die cutting and digital finishing.

LABELMASTERThe most complete and professional laser machine “roll to roll” for die cutting and digital finishing. -

DRAGONThe compact laser machine for cutting and marking.

DRAGONThe compact laser machine for cutting and marking.

CASE SHOW

SEI S.P.A.

Operational headquarters:

Via R. Ruffilli, 1

24035 Curno (BG) Italy

Ph. +39 035 4376016

info@seilaser.com

SEI S.p.A.

Production site

Via San Cassiano, 2

24030 Mapello (BG) Italy

T. +39 035 4376016

info@seilaser.com

SEI Laser Converting

Via Praz dai Trois, 16

33030 Buja (UD) Italy

T. +39 0432 1715827

F. +39 0432 1715828

info@seiconverting.it

SEI Deutschland Gmbh

Moosweg 9

D-82386 Huglfng - Germany

T. +49 8802 913600

F. +49 8802 9136066

info@seilaser.de

SEI Laser France

Le Korner

17 Rue du Prof. Jean Bernard

69007 Lyon - France

T. +33 4 37 70 48 93

france@seilaser.com

SEI Laser Systems (SHAOXING) Co., Ltd is a branch of SEI S.p.A.

All rights reserved: SEI Laser Sysytems(SHAOXING)Co., Ltd

National service hotline: 0575-83933766 Email: info@seilaserasia.com

Address: No.128, Zheduan Road, Pukou Development, Shengzhou, Zhejiang, China